Construction Leaders, Elected Officials Discuss Key Projects at HVCIP Luncheon

CHESTER, NY—The 10th annual Hudson Valley Construction Industry Partnership (HVCIP) luncheon at the Glenmere Mansion here on Tues., April 8, drew a record attendance of

New Federal Funding to Clarkstown For DPW Project to Combat Flooding

WEST NYACK, NY—The Town of Clarkstown announced it will receive more than $2.1 million in federal funding to fix conditions that cause widespread flooding and

Argenio Brothers Start $11M Roundabout At Key Intersection Near Vassar College

POUGHKEEPSIE, NY—New York State officials announced on April 5 that work will soon begin on a $11.4-million project to reconfigure the intersection of State Route

Bridge Authority Hosts M/WBE & SDVOB Meet & Greet

NEWBURGH, NY– The New York State Bridge Authority held its first-ever M/WBE & SDVOB Meet & Greet event on March 28 at the Newburgh campus

Commentary – PLAs Offer Accountability, Efficiencies On Large-Scale SUNY Building Projects

With the annual-budget negotiations in Albany now in overtime, blue collar workers are calling on policymakers to pass legislation that will restore accountability and bring

Appeals Court Lacks Jurisdiction To Hear Prevailing Wage Challenge

ALBANY—The Appellate Division of the New York State Supreme Court affirmed on Thurs., April 11, an initial decision rendered last fall by Supreme Court Justice

Attorney’s Column – Court Holds that Vague Arbitration Clause Is Still Sufficient to Compel Parties to Arbitrate

One clause that is often overlooked as boilerplate when negotiating a construction contract is the arbitration or, more broadly, ADR (Alternative Dispute Resolution) clause. There

Construction Sector Must Contend With Legal Marijuana in the Workforce

NAPLES, FL—Legal marijuana has become a major concern for construction employers with statistics showing it is contributing to more accidents, worsening the health of workers

Washington Update – Feds Award $24M Flood Mitigation In Westchester

WASHINGTON—U.S. Senate Majority Leader Charles E. Schumer announced on April 8 a total of $23,960,000 in federal funding has been approved to strengthen flood mitigation

Albany Update – NY State Environmental Facilities Corp. Closes $717-Million Bond Sale

ALBANY—President and CEO Maureen A. Coleman announced on April 2 that the New York State Environmental Facilities Corporation had successfully closed a $717-million bond sale

Hudson Valley Students Learn About Trade Skills, Careers at 24th Annual Construction Career Day

SUFFERN, NY—High school students from across the Hudson Valley met with building trade experts to participate in skills-building activities and learn about union careers at

Students Explore Career Opportunities At Annual Union Apprenticeship Expo

More than 700 students from 34 schools attended the expo on April 12 at Rockland Community College in Suffern.

Financial Management – ESOPs Offer Smooth Exit Strategies for Owners

It’s a conundrum more common than you might think: the owner (or owners) of a privately held, mid-size construction company is getting older and considering

What’s New & Who’s News

A roundup of what’s new and who’s in the news both locally and in the state.

Safety Watch – Company Liable for Failing to Document Violations of Safety Policy Regulations

In this era of labor shortages and the constant need to secure adequate staffing, construction companies have to balance the practical needs of their business

Economic Outlook – Lower Hudson Valley Successes Fuel Rising Housing Prices, Stoking Demand

The recent economic trends in the Lower Hudson Valley will have far-reaching implications for the region’s future. A thriving job market, flourishing commercial real estate

NYS Senate, Assembly Hike Funding Levels In FY2025 Budget for Hudson Valley Roads

TARRYTOWN—The advocacy efforts of the Hudson Valley region’s construction industry, led by the Construction Industry Council of Westchester & Hudson Valley, Inc., and organized union

Region’s Union Building Trades Leaders Map Out Major Project Pipeline for 2024

TARRYTOWN—Attendees of the Hudson Valley Construction Industry Partnership convention late last month in Naples, FL attended a host of highly informative presentations and roundtable discussions

County Executive Latimer Signs Nearly $53 Million Glen Island Bridge Bond Act

WHITE PLAINS—In his Seventh State of the County address on March 14, Westchester County Executive George Latimer signed the $52.8-million Glen Island Bridge construction Bond

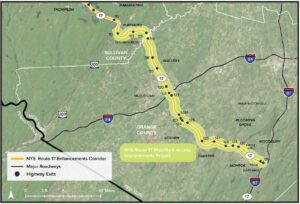

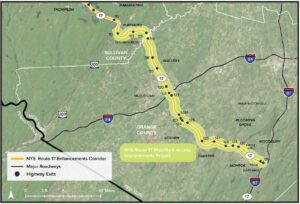

Guest Viewpoint – Route 17 Upgrade Will Enhance Safety, Mobility, Create Meaningful Jobs to Boost the Economy

When faced with challenges, leaders act. Problems require solutions, and if ignored, problems often become worse over time. A present-day case in point is Route

Attorney’s Column – GC’s Exaggerated Mechanic’s Lien Sinks Claim To Recover and Drowns its Subs in the Process

It’s always a bad idea to exaggerate the amount of a mechanic’s lien. While the exaggerating lienor may succeed in getting the attention of

Despite Optimism for Select Sectors, CEO Confidence Index Hits Near Lows

HYDE PARK, NY—A survey released on March 5 by the Siena College Research Institute of more than 500 upstate business leaders showed optimism that several

Biden FY25 Budget Seeks Heavy Spending For DOT, Army Corps

WASHINGTON—Thanks to the funding levels that are part of the $1.2 trillion IIJA, President Joe Biden’s budget proposal for fiscal year 2025 is sticking with

PSC Approves $57.8M Rockland Power Line

ALBANY —The New York State Public Service Commission recently approved plans by Orange and Rockland Utilities, Inc., for a new two-year electric system construction project,

Safety Watch – Fall Protection Must Be Provided to All Employees Working at Heights Greater than Six Feet

The Occupational Safety and Health Review Commission’s decision in Secretary of Labor v. Gate Precast Company reaffirms the safety requirements for construction companies that have

HVCIP Mid-Winter Meeting

HVCIP MID-WINTER MEETING

Ritz-Carlton, Naples, Florida • February 25 – February 29, 2024. 175 Members and Guests Convene to Discuss Management & Labor Concerns, Contracting

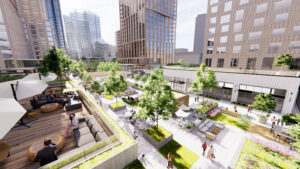

Yonkers IDA Helps Advance Teutonia Hall Project With $17.5M Incentives for Riverfront Development

YONKERS, NY—The long-anticipated redevelopment of the Teutonia Hall site on Buena Vista Avenue here is primed to move forward following final approval of financial incentives

Orange County Advanced Manufacturing Project Secures New York State Shovel-Ready Grant

MONTGOMERY, NY—A proposed project to locate a multi-building advanced manufacturing complex at the Aden Brook Commerce Park here was one of seven winners of the

Financial Management – Keep Good Records on PPP Loan Forgiveness. Lookback on SBA Challenge is Up to 10 Years

Many companies that have submitted documentation to the Small Business Association and that have had Paycheck Protection Program loans forgiven may think they are home

Making a Career of it

Making a Career of It Joseph Szabo Journeyman – Carpenters Local Union 279 Age: 36 Recent Employers: WD Installations, Inc. Recent Projects: Lasdon Park main

What’s New & Who’s News

A roundup of what’s new and who’s in the news both locally and in the state.

Building Trades Confident Road, Energy, Sewer Work Will Lead to Busy 2024

TARRYTOWN—Union building-trades officials in the Lower Hudson Valley express confidence that despite the economic headwinds and challenges of last year, several of the main economic

NYSDOT Lists 42 Projects, Valued at $376M, For Mid-Hudson Anticipated Lettings in 2024

POUGHKEEPSIE, NY—The New York State Department of Transportation recently released its anticipated project list for the 2024 letting season for the seven counties in the

TRIP Report Calculates Poor Roads, Bridges Cost New York City Area Motorists Nearly $37 Billion

NEW YORK—Roads and bridges that are deteriorated, congested or lack some desirable safety features cost New York motorists a total of $36.7 billion statewide annually—$

Coalition Demands More State Funding To Repair Hudson Valley’s Crumbling Roads

ELMSFORD, NY—A major coalition led by the Construction Industry Council of Westchester & Hudson Valley and construction trade unions is demanding that state lawmakers allocate

Attorney’s Column – Relying on Drawings Alone for Calculating Bid Failed to Show a Project’s True On-site Conditions

When first deciding to undertake a construction project, be it public or private work, contractors often start by reviewing the drawings—the graphic representation of what

Poughkeepsie Firm Named Apparent Low Bidder On Mid-Hudson Forensic Hospital Asbestos Job

ALBANY—The New York State Dormitory Authority has reported on its website that an apparent low bidder has been named for the first project in what

Safety Watch – Tragedy Illustrates Why Contractors Must Coordinate With Engineers to Establish and Update Rigging Plans

The decision in Secretary of Labor v. Tower King, II, Inc. should serve as a reminder to the construction industry, and companies specifically involved in

Annual CIC NYSDOT Region 8 Construction Safety Seminar

HYDE PARK, NY—The annual CIC/NYSDOT Region 8 Safety Seminar held at the Culinary Institute of America here on Tues., Jan. 30, drew a record attendance

Financial Management – Design-Build Procurement to Shape Future Of Construction for City of New York: DDC

In an effort to increase efficiency and reduce complexity in the construction process, the recently appointed Associate Commissioner of Alternative Delivery for New York City’s

Albany Update – NY State Awards $215M In Water Quality Funding

ALBANY—In separate announcements on Feb. 15, New York announced awards of more than $166 million in grants to 187 water quality projects throughout the state.

Washington Update – New EPA Air Quality Standard Termed an Overreach by ARTBA

WASHINGTON — The Biden-Harris Administration on Feb. 7 finalized a significantly stronger air quality standard that officials say will better protect America’s families, workers, and

Teamsters L.U. 456 Creates On-the-Job Trainee Program

ELMSFORD, NY—Teamsters Local 456 has created an on-the-job training program that enables a CDL-licensed driver/trainee to ride along in construction vehicles with an experienced driver/employee

Westchester IDA Marks Banner Year in 2023 With $2B, Propelled by Regeneron Expansion

WHITE PLAINS—The $1.8-billion expansion of Regeneron Pharmaceuticals has once again put economic development activity incentivized by the Westchester County Industrial Development Agency in the billions

Local Sales Taxes Grew 4.2% in NY State To $23 Billion in 2023, Comptroller Reports

ALBANY—Local government sales tax collections in New York State, fueled by growth in New York City sales taxes, totaled $23 billion in calendar year 2023,

Real Estate Broker’s Forecast Sounds Alarm on Office Sector

WHITE PLAINS—A panel of real estate brokers and developers offered a candid and unvarnished assessment of Westchester County’s multifamily, industrial, medical and office markets heading

Putnam County Exec. Calls for Restoration Of $60-Million Reduction to CHIPS Program

ALBANY—In testimony provided at the New York State Joint Legislative Public Hearing on the 2024 Executive Budget on Transportation earlier this month, Putnam County Executive

Filings for Large Multifamily Projects In NYC Remain at Historic Lows: REBNY

NEW YORK—The Real Estate Board of New York’s recently released New Building Construction Pipeline Report for the fourth quarter of 2023 states that New York

Viewpoint – Rockland’s Office of Buildings & Codes Issues Record Number of Violations, Fines Since 2022 – by Ed Day

Two years ago this month, we fulfilled an order by New York State Department of State (NYSDOS) to assume all functions and responsibilities of the

Economic Outlook – The Economic Effects of Cyber Attack

In our interconnected world, where the global economy relies heavily on digital infrastructure, the specter of cyber attacks looms large. Federal regulators often have said

White Plains Granted $10M in Downtown Revitalization Funding by New York State

WHITE PLAINS, NY—The City of White Plains was honored this month as a recipient of this year’s Downtown Revitalization Initiative Mid-Hudson Region and will receive

What’s New & Who’s News

A roundup of what’s new and who’s in the news both locally and in the state.

Gov. Hochul Seeks Large NYC Projects, Housing, Climate Change Goals in Her FY25 Proposed Budget

ALBANY—Gov. Kathy Hochul used her two spotlight appearances here this month to lay the groundwork for what her administration will seek in the annual budget

‘Blistering Pace’ of Growth in Bridge, Highway Construction, ARTBA Reports

WASHINGTON—Roadbuilders and their suppliers can expect a banner year in 2024, with industry experts projecting record spending on infrastructure projects thanks to the bipartisan Infrastructure

NYSDOT Updates Public on Progress On Rte. 17/I-86 Conversion/Exit 122 Job

TOWN OF WALLKILL, NY—The New York State Department of Transportation hosted public information sessions on Jan. 17 at the Town of Wallkill Community Center and

CIC Marks Milestone 45th Anniversary in 2024 With Special Presentations Planned at Events

TARRYTOWN, NY—The Construction Industry Council is celebrating its 45th anniversary this year with a host of events to mark the milestone since its first full

Attorney’s Column – Court Frowns on Claims Asserted Outside A Contractor’s Own Chain of Contract Privity

Anyone who has undertaken a construction project knows there are many activities to be coordinated, with many different people performing these activities. It is also

Warmer Winter Helping Construction DPW Projects Advance in Region

CHESTNUT RIDGE, NY—The head of the Rockland County Highway Department recently told CONSTRUCTION NEWS that these past two milder winters in the region has allowed

Next Generation Leader – Andrew Griffin

Next Gen Leaders Profiles of the Industry’s New Generation Andrew Griffin Age: 25 Current Employer: Corgan / NYC Position / Job Title: Project Specialist College

Teamsters L.U. 456 Hold Session on Drug Testing Protocols for CDL Employers, Owner/Operators

ELMSFORD, NY—Teamsters Local 456 held an information session on Jan. 11 at the union’s headquarters here, entitled “Drug Testing Protocols & Procedures,” for companies with

NYC Metro Housing Costs Soar by 68% in Last Decade

ALBANY—Housing costs in New York City and the surrounding suburbs have skyrocketed by more than 68% over the last decade, the largest increase among selected

Safety Watch – Install Traffic Control Devices, Legible Control Signs At Points of Hazard During Roadwork Activities

The decision in Secretary of Labor v. Brubacher Excavating Inc. & Traffic Control Services reminds us that construction companies conducting paving and excavation operations in

Financial Management – NYC Banking on Surge in Transit-Oriented Projects

With transit-oriented development projects on the rise, the Port Authority of New York and New Jersey is also continuing its redevelopment efforts at three major

Albany Update – State Opens Applications for $325M In Grants For Clean Water Infrastructure Projects

ALBANY—New York State is making $325 million in grants available for clean water infrastructure projects through the next round of the state’s Water Infrastructure Improvement

Regeneron Buys Avon Property in Suffern; Plans $138M Spend for New R&D Complex

SUFFERN, NY—In addition to the $1.8-billion expansion Regeneron Pharmaceuticals is now advancing in Westchester County, the company announced it will invest another $138 million in

What’s New & Who’s News

A roundup of what’s new and who’s in the news both locally and in the state.

$450M Mid-Hudson Psychiatric Center To be Built with PLA for Local Trades

NEW HAMPTON, NY—The New York State Dormitory Authority said on Dec. 14 that it has released the first bid in connection with the “New Forensic

Federal Infrastructure Law’s Impacts Felt Increasingly Across America

WASHINGTON—States have committed federal funds to support more than 56,000 eligible transportation improvements in all 50 states during the last two years, spanning nearly every

New York State to Chip in $1 Billion For $10B Albany Nanotech Complex

ALBANY—New York State announced on Dec. 11 a $10-billion partnership with leaders from the semiconductor industry, including Armonk-based IBM, Micron, Applied Materials, Tokyo Electron, and

Millions of Construction Workers Are Illegally Misclassified, Costing Government, Taxpayers $22 Billion in Lost Revenues

A pernicious employment practice—called misclassification— is used by unscrupulous employers to avoid paying their share of payroll taxes and to evade certain responsibilities and liabilities

Con Edison Ends Westchester County Natural Gas Moratorium

ARMONK, NY—Natural gas hookups are coming back to Westchester County after a fourand- a-half-year pause. Con Edison is set to end the moratorium affecting most

Attorney’s Column – New Law Creates Confusion in Attempt to Clarify Substantial Completion and Maximum Retainage

In 2002, the New York State Legislature attempted to address the problem of perpetually late payments to contractors and subcontractors in the private sector by

Next Generation Leader – Taylor Reilly

Next Gen Leaders Profiles of the Industry’s New Generation Taylor Reilly Age: 23 Louis G. Nappi Scholarship received: 2018, 2019 Title & Employer: Wholesale Florist,

Albany Update – More Than 1,000 Speeding Tickets Issued In Work Zones in Hudson Valley Region

ALBANY—As construction throughout much of New York State begins to wind down with winter weather setting in, New York State officials recently highlighted the year-end

Safety Watch – Adequate Lock-Out/Tag-Out Systems Must Be In Place to Prevent Employee Injuries: OSHASafety Watch –

The decision in Secretary of Labor v. Ward Vessel & Exchange Corporation reminds us that construction companies must have adequate lock-out/ tag-out systems in place

Congressman Mike Lawler Discusses ‘Hot Topics’

ELMSFORD, NY—Congressman Mike Lawler (R-17CD) met with more than 60 members of the union Building Trades on Nov. 28 at the Teamsters Local 456 Union

Financial Management – An Update on Research and Development Credits

The availability of the Internal Revenue Section (IRC) Section 41 Research and Development (“R&D”) tax credit for construction companies stems from the recognition by the

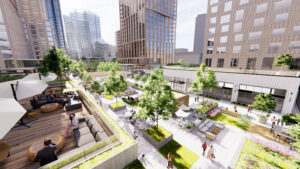

Finally, MGM Resorts Unveils Empire City Expansion Plan

YONKERS—MGM Resorts International unveiled its vision late last month to transition Empire City Casino by MGM Resorts into a world-class entertainment destination—with the title of

Creedmore Massive Housing Plan Redo In Queens Gets Major Boost from Albany

ALBANY—The Creedmoor Community Master Plan, a massive mixed-use project to redevelop underutilized land at the 125-acre Creedmoor Psychiatric Center campus in Eastern Queens, received a

NYPA Seeks New Corporate HQ In Downtown White Plains CBD

WHITE PLAINS—The New York Power Authority is currently reviewing proposals for a brand new 250,000-square-foot Class A state-of-the-art corporate headquarters in Downtown White Plains and

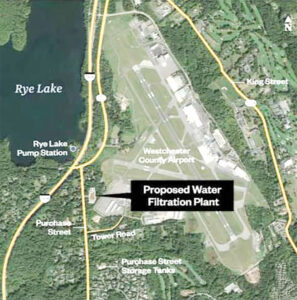

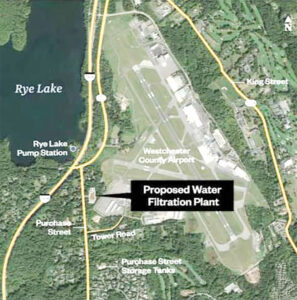

State to Fund $30M for Rye Lake Filtration Plant, One of 156 Local Water Infrastructure Projects

ALBANY—In what will be the first funding awarded through the $4.2-billion “Clean Water, Clean Air, and Green Jobs Environmental Bond Act of 2022,” New York

Economic Outlook – Unpacking the U.S. Dollar’s Complicated Role As the Reserve Currency to Stabilize Markets

Unpacking the U.S. Dollar’s Complicated Role As the Reserve Currency to Stabilize Markets

The value of a nation’s currency (in this case the U.S. dollar)

South Bronx Hailed for Economic Growth Despite COVID Pandemic Challenges: Report

ALBANY—The COVID-19 pandemic hit the South Bronx especially hard, but the area’s economy has shown resiliency, according to a report released recently by New York

What’s New & Who’s News

A roundup of what’s new and who’s in the news both locally and in the state.

Albany Update – Yonkers Contracting Completes Nearly $45M Pavement Improvement Project on Section of NYS Thruway

ALBANY—New York State officials recently reported the completion of a $44.6-million pavement improvement project on the New York State Thruway I-87 in a critical corridor

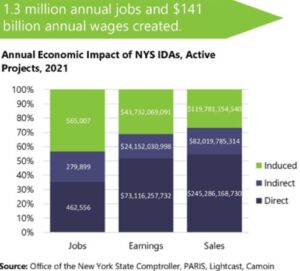

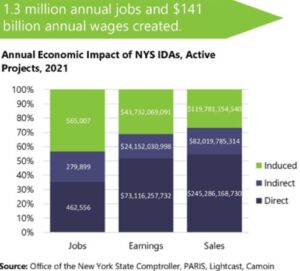

Report: New York State IDAs Generated $141 Billion In Wages; Created, Retained 1.3-Million Jobs in 2021

ALBANY—In light of some criticism being leveled against Industrial Development Agencies in New York State, particularly the need and financial returns of incentives granted to

Rockland Christens New $40-Million Complex That Houses County’s Highway Department

CHESTNUT RIDGE, NY—A project in Rockland County that has been debated, advertised for bid, withdrawn, then moth-balled and delayed for nearly six decades, has finally

Guest Viewpoint – Misclassification of Workers Undermines Fair Construction Practices, Hurts All Trades

In the cutthroat competition of the construction industry, the relationship between employers and workers can be difficult to navigate. Something as simple as how you

13th Annual CAI Seminar for P.E.s Draws Dozens to Earn 6 PDH/HSW Credits

TARRYTOWN, NY—The always-popular professional development seminar, presented annually by the Construction Advancement Institute (CAI), drew a capacity audience last month for a program entitled “ENGINEERING:

Attorney’s Column – Court: ‘Adjoining’ Properties to be Protected During Excavation Need Not Be Abutting

It has long been the law that owners and contractors who perform construction activities on a property can be held liable for damages caused to

Obituary – O.L. ‘Peter’ Bibeau

BOCA RATON, FLA—Harold Vogt, the longtime leader of The County Chamber of Commerce (now operating as The Business Council of Westchester), died on Sept. 28

Obituary – Mortimer L. Downey, III

Mortimer L. Downey III, who for 65 years was a top official and advocate for mass transit, passed away on Nov. 2 at the age

100 Years Strong – H.O. Penn Celebrates Centennial Of Challenges and Achievements

POUGHKEEPSIE, NY—H.O. Penn staged a grand gathering at its headquarters here in early September to cap off the company’s ongoing centennial celebration in business. Scores

From the Archives – H.O. Penn Meets The Challenges of 9/11

NEW YORK—Four months after the attacks that devasted lower Manhattan, Chief Executive Officer Thomas Cleveland had a newfound appreciation for his company and the employees

Soaring Road Construction Costs Threaten State and Local Projects

TARRYTOWN, NY—Highway and street materials have increased 21% since last year due to hikes in petroleum-based energy costs and other material products in addition to

Safety Watch – Tree Trimming Work Requires Documented Training, Feasible Methods to Reduce and Eliminate Harm

The recent decision in Secretary of Labor v. Asplundh Tree Expert, LLC discussed feasible and effective methods to reduce or eliminate harm to employees performing

What’s New & Who’s News

A roundup of what’s new and who’s in the news both locally and in the state.

Financial Management – Both Opportunities and Challenges for Construction Loom in the Face of Infrastructure and Resiliency

The Inflation Reduction Act’s gift of funding and new capital projects on the horizon are promising and exciting for all in our industry. However, as

Albany Update – Business Council of NYS Sounds Alarm On Impacts of State’s Energy Policies

ALBANY—The Business Council of New York State announced recently the first of several state-wide information campaigns designed to educate New York voters on the impacts

NYC Region Enters New Era of Mega Projects As Feds Appropriate $10B+ for Tunnels, Bridges

WASHINGTON—In a series of announcements in the past few days, the Biden Administration has pledged a total of $6.76 billion in federal infrastructure funding for

No Recession Looming in Construction Despite Vexing Headwinds of Inflation, Labor Shortages

TARRYTOWN—Armies of economic pundits appear mixed in their predictions about where the U.S. economy is going in 2024. Is it heading into recession or to

Latimer Proposes $474M Capital Budget

WHITE PLAINS—Westchester County Executive George Latimer and administration staff released on Oct. 17 a $473.7-million proposed 2024 Capital Budget that is highlighted by significant road

Mixed-Use $2.5-Billion Redevelopment Proposed for Galleria Mall in White Plains

WHITE PLAINS—In what is clearly the most anticipated development proposal to hit the desks of city leaders in decades, Pacific Retail Capital Partners, The Cappelli

Lt. Gov. Delgado Touts Infrastructure Projects At CIC-BCA Fall Membership Meeting Oct. 12

TARRYTOWN, NY—In the 47-year history of the Construction Industry Council, there has never been a guest speaker at an annual membership meeting quite like the

Obituary – Harold Vogt

BOCA RATON, FLA—Harold Vogt, the longtime leader of The County Chamber of Commerce (now operating as The Business Council of Westchester), died on Sept. 28

CIC-BCA 2023 Fall Membership Meeting

CIC-BCA’s Fall Membership meeting was attended by more than 110 Members, Guests and Exhibitors.

Attorney’s Column – Court Clarifies that ‘Scaffold Law’ Claims Fail Where Worker was ‘Sole Proximate Cause’ of Injuries

We discussed last month how Sections 200, 240(1), and 241(6) of New York’s Labor Law, which are commonly referred to as New York’s “Scaffold Law,”

Making a Career of it

Joann Gentile finally found the pathway to her career one snowy night, around 2:00 am, when she queued up— along with 100 other hopeful applicants

Mount Pleasant Seeks Engineers to Study Ongoing Flooding and Pursue Grant Money

MOUNT PLEASANT, NY—In response to the recent flooding emergencies that continue to inundate sections of the Town of Mount Pleasant during significant storms, the Town

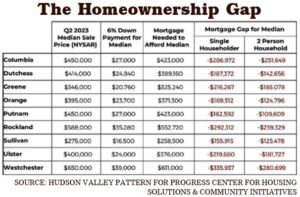

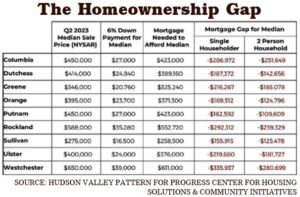

Economic Outlook – Housing Prices Still Too High for Many Who Want to Call Hudson Valley Home

Housing market activity remains particularly weak, which is being attributed to rising mortgage rates, elevated home prices and constrained housing inventory. According to Forbes, this

Wall Street’s Profits Totaled $13B in First Half of 2023

ALBANY—Wall Street’s 2023 first half profits of $13 billion were down 4.3% from the same period last year but tracked the industry’s return to pre-pandemic

Feds to Fund $7.5B Credit Aid for Dam Projects

WASHINGTON—The U.S. Army Corps of Engineers reported on Sept. 20 that it is accepting applications for a new $7.5-billion credit assistance program, the Corps Water

NYCEDC Seeks RFP for Redevelopement Of Landmark Kingsbridge Armory Project

NEW YORK—The New York City Economic Development Corporation released a Request for Proposals (RFP) on Sept. 25 for a developer to lease, redevelop, and operate

Safety Watch – Industrial Vehicle Accident Underscores Need for Robust Training, Safety Programs

The recent decision in Secretary of Labor v. Americold Logistics, LLC reaffirms the need for construction companies to provide proper training and establish rules and

Albany Update – Business Council of NYS Sounds Alarm On Impacts of State’s Energy Policies

ALBANY—The Business Council of New York State announced recently the first of several state-wide information campaigns designed to educate New York voters on the impacts

Financial Management – AI Likely to Advance Construction Productivity In Design, Bidding, Performance, Management

Artificial Intelligence (AI) in construction has the potential to enable the industry to overcome some of the unprecedented obstacles we have faced in recent years.

Washington Update – FHWA Opens Applications for Nearly $10 Billion for Large Bridge Projects

WASHINGTON – The U.S. Department of Transportation’s Federal Highway Administration opened applications on Sept. 29 for nearly $10 billion in funding for fiscal years 2023-2026

Dutchess County Justice & Transition Center to Open $20M Under Budget

POUGHKEEPSIE NY—Dutchess County Executive William F.X. O’Neil joined Dutchess County Sheriff Kirk Imperati in announcing on Oct. 10 that the new Dutchess County Justice &

P.A. to House Construction Activity Under New Support Facility at JFK

NEW YORK–The Port Authority of New York and New Jersey announced on Sept. 27 that operations have started at a new construction support facility at

NYSDOT Region 8 Lettings on Track With Significant Paving, Traffic Signal Projects

TARRYTOWN—An analysis of both projects awarded so far in 2023 and those scheduled to be bid for the remainder of the year and into early

Homeownership, Rent Costs Out of Reach For Many Living in H.V. Counties: Report

NEWBURGH—It’s been a tough year for renters and home buyers in most of the Hudson Valley, and if one study is any indication, things don’t

Labor Leaders Applaud Ulster County Law Strengthening Rules for Apprenticeships

KINGSTON, NY–Local labor leaders, apprentices and elected officials joined Ulster County Executive Jen Metzger on Sept. 6 in Kingston for a ceremonial signing of local

COMMENTARY – More in U.S. See Unions Strengthening And Want It That Way: Gallup Survey

WASHINGTON—Labor unions continue to enjoy high support in the U.S., with 67% of Americans approving of them, which is similar to the elevated level seen

Attorney’s Column – Court Clarifies that Scaffold Law Only Applies to Workers

Sections 200, 240(1), and 241(6) of New York’s Labor Law are commonly referred to as New York’s “Scaffold Law.” The Scaffold Law was enacted back

Construction Begins in Queens to Receive 339-Mile Champlain Hudson Power Express

NEW YORK—Construction is underway on the converter station for the 339-Mile Champlain Hudson Power Express (CHPE) transmission line terminating in Astoria, Queens.

Woodbury Common Outlets Submits Plans for $250 Million Expansion

CENTRAL VALLEY, NY—Who said brick and mortar retail is dead. Woodbury Common Premium Outlets has new plans to dramatically grow the retail enterprise here

3rd Annual CIC Softball Game Raises $20K for Ukrainian Humanitarian Relief

TARRYTOWN, NY—Looking to extend its bragging rights for another year, The Pavers led by Stephen Hocker of ECCO III Enterprises faced off against The Builders,

Mount Vernon Agrees to Spend $100M To Repair Clean Water, Sewer Violations

NEW YORK—Damian Williams, the United States Attorney for the Southern District of New York, and Lisa F. Garcia, the Regional Administrator for Region 2 of

New York Building Congress Launches New ‘Infrastructure Action Council’

NEW YORK—The New York Building Congress has launched the Infrastructure Action Council (IAC), a group of building industry leaders driving infrastructure advocacy efforts at the

Safety Watch – Companies Engaging in Excavation Work Must Follow Safety Regs to Avoid Cave-Ins, Trench Collapses

As is well documented and reported, a cave-in or trench collapse can lead to serious injuries and even death. The recent decision in Secretary of

Thruway Board Approves Toll Hikes for 2024

ALBANY—The New York State Thruway Authority Board of Directors approved on Sept. 18 toll increases on the New York State Thruway system following a 10-month

An Emergency Preparedness Plan ‘May Have Saved This Man’s Life’

TARRYTOWN, NY—For contractors, most Mondays begin with the usual routine of managing planned work assignments with enough latitude built in to handle the curveballs that

Financial Management – Rising Cost of Money’s Impact on Construction: How the Sector is Managing Interest-Rate Pressures

In late July 2023, the Federal Reserve raised interest rates again by a quarter of a percentage point to 5.5%, reaching its highest level in

Westchester Medical Center Secures $195M In Bond Financing for New Patient Care Tower

WHITE PLAINS—Westchester County’s Local Development Corporation (LDC)voted on Aug. 23 final approval of $195-million in tax-exempt bond financing for the development of a new 162,626-square-foot

Movie/TV Studio Campus at West Side’s Pier 94 Advances

NEW YORK—The developers of the long-anticipated movie/television studio project at Pier 94 on Manhattan’s West Side say that construction is expected to begin this fall

Pfizer Division Renews, Expands Lease at Hudson Valley iCampus in Rockland

PEARL RIVER, NY—A division of pharmaceutical giant Pfizer Inc. has signed a lease renewal and expansion totaling more than 151,000 square feet of space at

Washington Update – Revised EPA Waters of the U.S. Rule Prompts Protest by Industry Groups

WASHINGTON—The American Road & Transportation Builders Association (ARTBA) and the National Association of Home Builders were among the first business organizations to protest the revised

Gateway Development Awards Two Major Contracts

NEWARK, NJ—The Gateway Development Commission at its Board of Commissioners meeting on Sept. 11 approved first direct contract awards: two contracts for construction and construction

Next Generation Leader – Nicola Altomare

Next Gen Leaders Profiles of the Industry’s New Generation Nicola Altomare Current Employer: aRoboticsCompany—Ossining, NY Job Title: Mechatronics Engineer Age: 23 Accomplishments: Awarded five annual

NYC Has Been Allocated Nearly $1 Billion In Total Federal Infrastructure Funding

NEW YORK—New York City Mayor Eric Adams announced earlier this month that New York City has been allocated for $987 million in federal infrastructure funding

What’s New & Who’s News

A roundup of what’s new and who’s in the news both locally and in the state.

Albany Update – Job Flexibility Tops Worker Priorities; Worker Retention Leads for Employers

ALBANY—The New York State Department of Labor released the results of its 2023 Workforce Development Survey, and workers continue to say that flexibility in their

Municipalities Face Numerous Hurdles To Access Environmental Bond Funds

WHITE PLAINS—Despite the historic funding levels made available through the $4.2-billion environmental bond act that voters approved last November, the construction and environmental groups that

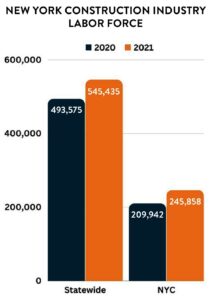

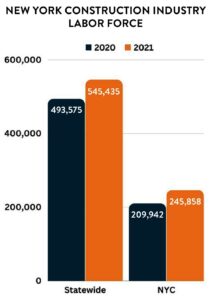

State’s Diversifying Construction Workforce To Surpass Pre-Pandemic Levels Soon: Report

NEW YORK—A recently released report by the New York Building Congress paints a very positive outlook for the state’s construction sector as the industry becomes

Popolopen Bridge Along Route 9W Reopened Following Repairs From Severe Flood Damage

HIGHLANDS, NY—U.S. Route 9W in the Town of Highlands in Orange County has reopened following the devastating floods that struck the Hudson Valley on

DOL Updates Prevailing Wage Laws Raising Workers’ Pay on Federal Jobs

WASHINGTON—The U.S. Department of Labor announced on Aug. 8 it will be “Updating the Davis-Bacon and Related Acts Regulation,” which sets the prevailing wages contractors

Obituary – Hugh G. ‘Jerry’ Keahon, Jr.

NEW WINDSOR, NY—Hugh G. “Jerry” Keahon, Jr., a fixture in the Hudson Valley concrete supply sector for more than five decades and a board member

Attorney’s Column – Court Rules Parties are Generally Free to Shorten The Period Within Which to Commence a Lawsuit

Construction contracts, like other contracts, are meant to define the relationship between the parties. In that regard, the parties are generally free to negotiate the

Economic Outlook – Ways to Adapt to Hybrid Work And the Changing Office Economy

The ripple effects of hybrid work (in office and at home) have been substantial. Untethered from their offices, residents have left urban centers and shifted

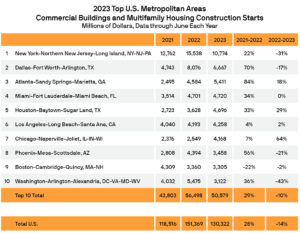

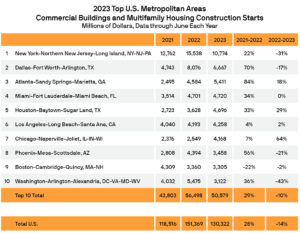

Commercial, Multifamily Starts in NYC Down 31%

HAMILTON, NJ—Recently released new data from Dodge Construction Network found that the value of commercial and multifamily construction starts across the top 10 metropolitan areas

Putnam Exec Byrne Hosts Public Meeting On Peekskill Hollow Road Construction Project

CARMEL, NY–Putnam County Executive Kevin Byrne hosted a townhall-style meeting on Aug. 3 to address Putnam Valley residents about the much-anticipated Peekskill Hollow Road construction

18 Students Share $90,000 in College Scholarships From CIC’s Louis G. Nappi Management-Labor Fund

TARRYTOWN, NY—Eighteen college and graduate students will begin the fall semester each with a $5,000 grant from the Louis G. Nappi Construction Labor-Management Scholarship Fund

Regional Roundup – New $24M Medical Examiner’s Office Underway in Orange

GOSHEN, NY—Orange County officials broke ground on Aug. 3 on a new Medical Examiner’s Office being built adjacent to the county’s Emergency Services Center on

Safety Watch – Company Owners Must Not Simply Delegate Its Worker Safety Programs to Employees

Power saws, shears, presses and other machines typically used in construction require one or more methods of machine guarding to protect operators from the hazards

Albany Update – $739M Kew Gardens Interchange Project Honored by American Assoc. of State Highway and Transportation

ALBANY—New York Gov. Kathy Hochul announced earlier this month that a major project recently completed by the New York State Department of Transportation—The Kew Gardens

Washington Update – 222,000 U.S. Bridges Need Repair; Price Tag: $319B

WASHINGTON—More than 222,000 U.S. bridges need major repair work or should be replaced, according to the American Road & Transportation Builders Association’s (ARTBA) analysis of

Financial Management – Successful Succession in a Family-Run Business Requires Planning for Construction Industry Owners

By their very nature, family businesses in the construction industry can thrive on the strength of relationships that run deeper than those between unrelated co-workers.

NY State, City Contribute $200M for Long Sought After Redevelopment of the Kingsbridge Armory in the Bronx

NEW YORK—If at first you don’t succeed, try, try again…and again. New York State Gov. Kathy Hochul and New York City Mayor Eric Adams announced

New Law Ensures Prevailing Wage on Road Utility Jobs

ALBANY—New York Gov. Kathy Hochul announced on Aug. 16 she had signed legislation (S.4887/A.5608) into law, enacting the “Roadway Quality Assurance Act,” strengthening New York’s

What’s New & Who’s News

A roundup of what’s new and who’s in the news both locally and in the state.

Widespread H.V. Storm Damage Likely to Cost Billions to Repair

WHITE PLAINS—The destruction caused by torrential rains and flooding that battered the region this month was historic in sections—and the expense is likely to be

Feds Commit $6.88 Billion in Historic Funding For Long-Delayed Hudson River Tunnel Project

NEW YORK—News on the long-delayed Gateway Project came in fast and furious over the past few weeks, culminating with the announcement on July 6 of

NY State Earmarks $516 Million Statewide To Repair, Replace, Local Bridges, Culverts

ALBANY— New York State said it award of more than $516 million in enhanced assistance for 216 projects to 141 local governments to rehabilitate and

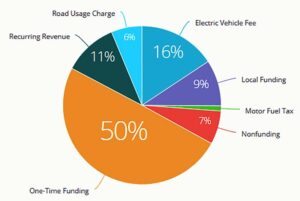

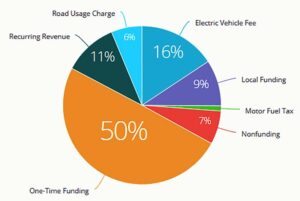

States Pass 24 Legislative Measures in 2023 To Increase New Transportation Investment

WASHINGTON—From general fund transfers to electric vehicle (EV) registration fees, 2023 has turned out to be a busy year for state transportation funding advocates. As

Skanska-Halmar JV Awarded $1.24 Billion Contract to Make Upgrades at JFK Airport

NEW YORK—Skanska, the global construction and development firm based in New York City, and joint venture partner, Halmar International, LLC, announced on June 26 the

Construction Advancement Institute Awards $75,000 In College Scholarships to Pursue STEM Subjects

Construction Advancement Institute Awards $75,000 In College Scholarships to Pursue STEM Subjects 15 Scholars from the Hudson Valley Region Named Recipients July 21, 2023 TARRYTOWN,

Attorney’s Column – Court Reminds Us That ‘Routine’ Releases, Waivers Of Lien Operate to Bar Claims That Accrued Prior

The release and waiver of lien is as ubiquitous on a construction project as the payment requisition form itself—and perhaps blueprints, as well. These documents

Second Phase of Second Ave. Subway Begins with Solicitation of First Contract

NEW YORK—The Metropolitan Transportation Authority is advancing Phase 2 of the Second Avenue Subway with the solicitation of the first contract for construction of the

Rockland County Signs Materials Deal With Tilcon New York

NEW CITY, NY—Rockland County posted on social media on May 28 that Rockland County Executive Ed Day signed a resolution in the amount of $250,000

Forecasted Demand for Electricity in NYC Shows ‘Reliability Supply Deficit’ by 2025, NYISO Reports

RENSSELAER, NY—As New York State continues its push for green and renewable energy sources, The New York Independent System Operator (NYISO) on July 14 released

Albany Update – Bruckner Expressway Bridge Rehab Begins

ALBANY—New York State officials announced recently the start of a $44.7-million project to rehabilitate the bridge carrying the Bruckner Expressway over Rosedale Avenue in the

Photo Gallery – CIC Golf Outing

Knollwood Country Club, Elmsford, NY

June 6, 2023 – 88 Golfers, 114 Dinner Guests

Participated in 66th Annual Golf Outing.

Safety Watch – Occupational Exposure Risks from Workplace Accidents Pose More Stringent Regulations for Employers

Construction companies that maintain in-house first aid responders who would conduct clean-up operations following an accident must be properly trained and the company must have

NYC DEP Delays Last Phase of Repairs To Delaware Aqueduct to October 2024

NEW YORK—The New York City Department of Environmental Protection announced late last month a schedule change for planned work on the Delaware Aqueduct, the world’s

Financial Management – New Ideas, Innovation Pushing Construction Ahead

What’s new in construction as the pandemic lies behind us? While construction has been through its share of suffering in a series of disruptive challenges

West Point Under Siege

The surrounding communities where flash flooding left cars stranded, homes in residential areas submerged and sections of roadways destroyed US Military Academy at West Point

Deadline for Resiliency Grants Extended by NYS to Aug. 11

ALBANY–Communities statewide that face aftermath recovery from the severe weather emergencies this month have more time to apply for certain resiliency-related state grants. The new

What’s New & Who’s News

A roundup of what’s new and who’s in the news both locally and in the state.

DOT Unveils Route 17 Timeline For Reviews, Bidding, Start Dates

TOWN OF WALLKILL, NY—Officials with the New York State Department of Transportation held a public hearing on June 1 at Wallkill Town Hall to update

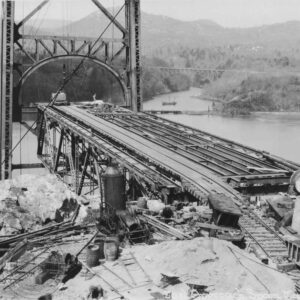

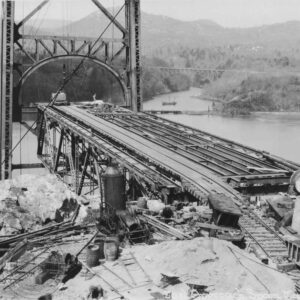

State Bridge Authority Launches Centennial Celebration of Iconic Bear Mountain Bridge

BEAR MOUNTAIN, NY—As Hudson River bridge crossings go, the cost of construction of the Bear Mountain Bridge was a real bargain.

Back when it opened

Philadelphia Bridge Collapse Shines Spotlight On Need to Improve Bridge Conditions in U.S.

TARRYTOWN—The names of failed bridges continue to haunt our nation’s transportation legacy. Mianus River, Schoharie Creek, Tennessee Hatchie River Bridge, Cypress Street, San Francisco-Oakland Bay

COMMENTARY – Congestion Pricing: The Whole World Is Watching; New York Has to Get it Right

NEW YORK—The polluted air in early June, affecting much of the U.S. from wildfires in Canada, should remind us that we are all connected on

Construction Groups Say Supreme Court Ruling May Advance Transportation Project Approvals

WASHINGTON—The U.S. Environmental Protection Agency’s campaign to regulate all U.S. ditches hit another roadblock on May 25. The U.S. Supreme Court agreed with the American

Attorney’s Column – Appellate Court Reminds Us That Not All Provisions Of Upstream Contract are Incorporated by Reference

As anyone in the construction industry knows, subcontracting is as widespread in the industry as hammers and nails. Given this state of affairs, it is

Next Generation Leader – Julia Apostolou

Next Gen Leaders Profiles of the Industry’s New Generation Julia Apostolou Current Employer: Kimley-Horn and Associates, Inc., White Plains, NY Job Title: Transportation Planning and

Economic Outlook – Artificial Intelligence (AI): Focus on the Economic Impacts

Toward the end of 2022 a computer program known as ChatGPT—a form of artificial intelligence—burst into the public consciousness with the possibility of revolutionizing communications.

Legislature Passes Prevailing Wage Law Covering Private Utility Contract Work

ALBANY—The New York State Legislature passed before the end of the legislative session last week the “Roadway Excavation Quality Assurance Act” (S4887, A5608), which “provides

Safety Watch – Handle With Care and With Proper Training

The use of potentially hazardous and dangerous substances such as propane, propylene and compressed oxygen, which are common in the construction industry, need to be

Financial Management – Legislation Makes 179D Deduction More Valuable for 2023

The 179D tax deduction provides building owners a deduction for new or remodeled commercial buildings that meet specific energy-efficient qualifications. This deduction is also available

Photo Gallery – BCA Golf Outing

Knollwood Country Club, Elmsford, NY

June 6, 2023 – 88 Golfers, 114 Dinner Guests

Participated in 66th Annual Golf Outing.

What’s New & Who’s News

A roundup of what’s new and who’s in the news both locally and in the state.

Thruway Seeks New Tolls To Fund Operations, Capital Plan Thru 2027 – Public Comments May 16

WEST NYACK, NY—Local motorists, truckers and residents voiced their opinions here at the Palisades Center on May 16 over the New York State Thruway Authority’s

Thruway Seeks New Tolls To Fund Operations, Capital Plan Through 2027 – TRIP Report Tells Why

ALBANY—As vehicle traffic returns to pre-pandemic levels, the New York State Thruway Authority is facing a significant funding backlog in coming years, according to a

Hudson Valley Saw Nearly 5,000 People Leave Region Prompted by Pandemic

NEWBURGH, NY—Despite the headlines of a population surge three years ago into the Hudson Valley region from New York City as Gothamists sought the safety

Real Estate, Government Officials Agree Housing Crisis is Real

RYE, NY—In the aftermath of Gov. Kathy Hochul’s failed “New York Housing Compact” bold initiative that called for the development of 800,000 new housing units

COMMENTARY – Congestion Pricing Program Works; Data from Other Cities Proves It

New York is poised to be the first city in the United States to implement a tolling program to combat traffic congestion and incentivize the

NYC Congestion Pricing Plan Reaches Key FEIS Milestone

NEW YORK—A triumvirate of government bodies released on May 12 the long-debated report that supports congestion pricing in Manhattan. The Final Environmental Assessment for the

Attorney’s Column – Court Holds That Wrap Up Exclusion Applies, Even Where Contractor Was Not Enrolled in Wrap-Up Insurance Program

As anyone who has had the displeasure of being on the defending end of a personal injury action knows, cross claims between various defendants (seeking

DOT Commissioner Extolls Speed Camera Plan In Statewide DOT, Thruway Authority Work Zones

TARRYTOWN, NY—Highway safety advocates are urging drivers to pay attention and slow down as part of the National Work Zone Awareness campaign this month. Construction

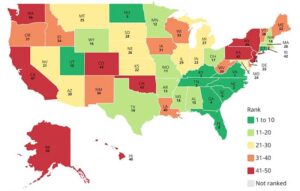

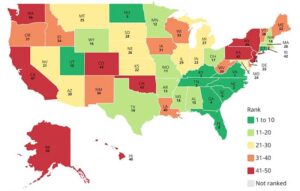

New York Highway System Ranks 49th in U.S. For Performance Condition, Cost Effectiveness

LOS ANGELES—New York’s highway system ranks 49th in the nation in overall cost-effectiveness and condition, according to the Annual Highway Report by the Reason Foundation

Albany Update – State Approves $51 Million For Clean Water Projects

ALBANY—The Environmental Facilities Corporation Board of Directors approved $51 million in funding that includes low-cost financing and previously announced grants that authorizes municipal access to

Mid-Hudson Council Seeks Grant Requests For Projects to Boost Housing, Infrastructure

ALBANY—The Mid-Hudson Regional Economic Development Council announced on May 17 the opening of the $150-million Mid-Hudson Momentum Fund grant application for mixed-use housing and infrastructure

Safety Watch – Perform an Engineering Survey Prior to a Demo Operation

To ensure the safety of workers, an engineering survey is required to be performed by a competent person prior to the start of a demolition

Financial Management – Construction Firms Adopt New Hiring Practices To Attract and Retain Top Talent and Skilled Labor

As the pandemic ushered in disruption in a number of areas such as supply chain procurement and the bidding process, the inability to find skilled

What’s New & Who’s News

A roundup of what’s new and who’s in the news both locally and in the state.

Mid-Hudson Leaders Expect Strong Construction Market

CHESTER, NY—Although some economists are predicting a recession later this year, construction activity in the Mid-Hudson Valley will continue to be strong in 2023, according

Vintage Lake Isle Masonry Dam To Finally See Long-Sought Repairs

EASTCHESTER, NY—Infrastructure rebuilding in the region took a major step forward when it was announced this month that federal and state monies are on the

Business Organizations Tell Westchester Delegation Housing Incentives Alone Will Not Work in County

TARRYTOWN—The chief executives of five major business organizations in Westchester County have jointly sent a letter to the Westchester State Delegation urging them that incentives

NYC’s Goal is to Convert Office Space into Housing

NEW YORK—A plan to address the needs to create more affordable housing in a post-pandemic New York would covert vacant office buildings into homes, thereby

Attorney’s Column – Owner’s Right Limited to Itemized Statement of Lien As Contract Was Fully Performed: Court

As this column has often noted, a mechanic’s lien is a powerful tool to help a contractor get paid. Because of the power of this

Washington Update – Infrastructure Investment Law Is Working: ARTBA

WASHINGTON—More than 36,000 transportation improvement projects, including at least one in every congressional district, have moved forward in the past 16 months as implementation of

Next Generation Leader – Timothy Kohany, EIT

Next Gen Leaders Profiles of the Industry’s New Generation Timothy Kohany, EIT Age: 37 Current Position: Assistant Project Engineer Employer: Siefert Associates – Construction Engineers

Economic Outlook – Holding the Debt Ceiling Hostage Threatens the Economy

What would happen if the U.S. government defaulted on its national debt? The Federal government has a borrowing constraint commonly known as the debt ceiling.

Photo Gallery – Students Explore Career Opportunities At Union Apprenticeship Expo

Rockland Community College • March 31

2023

- Construction News January 2023

- Construction News February 2023

- Construction News March 2023

- Construction News April 2023

- Construction News May 2023

- Construction News June 2023

- Construction News July 2023

- Construction News August 2023

- Construction News September 2023

- Construction News October 2023

- Construction News November 2023

- Construction News December 2023

2022

- Construction News January 2022

- Construction News February 2022

- Construction News March 2022

- Construction News April 2022

- Construction News May 2022

- Construction News June 2022

- Construction News July 2022

- Construction News August 2022

- Construction News September 2022

- Construction News October 2022

- Construction News November 2022

- Construction News December 2022

2021

- Construction News January 2021

- Construction News February 2021

- Construction News March 2021

- Construction News April 2021

- Construction News May 2021

- Construction News June 2021

- Construction News July 2021

- Construction News August 2021

- Construction News September 2021

- Construction News October 2021

- Construction News November 2021

- Construction News December 2021

2020

- Construction News January 2020

- Construction News February 2020

- Construction News March 2020

- Construction News April 2020

- Construction News May 2020

- Construction News June 2020

- Construction News July 2020

- Construction News August 2020

- Construction News September 2020

- Construction News October 2020

- Construction News November 2020

- Construction News December 2020

Construction Leaders, Elected Officials Discuss Key Projects at HVCIP Luncheon

CHESTER, NY—The 10th annual Hudson Valley Construction Industry Partnership (HVCIP) luncheon at the Glenmere Mansion here on Tues., April 8, drew a record attendance of

New Federal Funding to Clarkstown For DPW Project to Combat Flooding

WEST NYACK, NY—The Town of Clarkstown announced it will receive more than $2.1 million in federal funding to fix conditions that cause widespread flooding and

Argenio Brothers Start $11M Roundabout At Key Intersection Near Vassar College

POUGHKEEPSIE, NY—New York State officials announced on April 5 that work will soon begin on a $11.4-million project to reconfigure the intersection of State Route

Bridge Authority Hosts M/WBE & SDVOB Meet & Greet

NEWBURGH, NY– The New York State Bridge Authority held its first-ever M/WBE & SDVOB Meet & Greet event on March 28 at the Newburgh campus

Commentary – PLAs Offer Accountability, Efficiencies On Large-Scale SUNY Building Projects

With the annual-budget negotiations in Albany now in overtime, blue collar workers are calling on policymakers to pass legislation that will restore accountability and bring

Appeals Court Lacks Jurisdiction To Hear Prevailing Wage Challenge

ALBANY—The Appellate Division of the New York State Supreme Court affirmed on Thurs., April 11, an initial decision rendered last fall by Supreme Court Justice

Attorney’s Column – Court Holds that Vague Arbitration Clause Is Still Sufficient to Compel Parties to Arbitrate

One clause that is often overlooked as boilerplate when negotiating a construction contract is the arbitration or, more broadly, ADR (Alternative Dispute Resolution) clause. There

Construction Sector Must Contend With Legal Marijuana in the Workforce

NAPLES, FL—Legal marijuana has become a major concern for construction employers with statistics showing it is contributing to more accidents, worsening the health of workers

Washington Update – Feds Award $24M Flood Mitigation In Westchester

WASHINGTON—U.S. Senate Majority Leader Charles E. Schumer announced on April 8 a total of $23,960,000 in federal funding has been approved to strengthen flood mitigation

Albany Update – NY State Environmental Facilities Corp. Closes $717-Million Bond Sale

ALBANY—President and CEO Maureen A. Coleman announced on April 2 that the New York State Environmental Facilities Corporation had successfully closed a $717-million bond sale

Hudson Valley Students Learn About Trade Skills, Careers at 24th Annual Construction Career Day

SUFFERN, NY—High school students from across the Hudson Valley met with building trade experts to participate in skills-building activities and learn about union careers at

Students Explore Career Opportunities At Annual Union Apprenticeship Expo

More than 700 students from 34 schools attended the expo on April 12 at Rockland Community College in Suffern.

Financial Management – ESOPs Offer Smooth Exit Strategies for Owners

It’s a conundrum more common than you might think: the owner (or owners) of a privately held, mid-size construction company is getting older and considering

What’s New & Who’s News

A roundup of what’s new and who’s in the news both locally and in the state.

Safety Watch – Company Liable for Failing to Document Violations of Safety Policy Regulations

In this era of labor shortages and the constant need to secure adequate staffing, construction companies have to balance the practical needs of their business

Economic Outlook – Lower Hudson Valley Successes Fuel Rising Housing Prices, Stoking Demand

The recent economic trends in the Lower Hudson Valley will have far-reaching implications for the region’s future. A thriving job market, flourishing commercial real estate

NYS Senate, Assembly Hike Funding Levels In FY2025 Budget for Hudson Valley Roads

TARRYTOWN—The advocacy efforts of the Hudson Valley region’s construction industry, led by the Construction Industry Council of Westchester & Hudson Valley, Inc., and organized union

Region’s Union Building Trades Leaders Map Out Major Project Pipeline for 2024

TARRYTOWN—Attendees of the Hudson Valley Construction Industry Partnership convention late last month in Naples, FL attended a host of highly informative presentations and roundtable discussions

County Executive Latimer Signs Nearly $53 Million Glen Island Bridge Bond Act

WHITE PLAINS—In his Seventh State of the County address on March 14, Westchester County Executive George Latimer signed the $52.8-million Glen Island Bridge construction Bond

Guest Viewpoint – Route 17 Upgrade Will Enhance Safety, Mobility, Create Meaningful Jobs to Boost the Economy

When faced with challenges, leaders act. Problems require solutions, and if ignored, problems often become worse over time. A present-day case in point is Route

Attorney’s Column – GC’s Exaggerated Mechanic’s Lien Sinks Claim To Recover and Drowns its Subs in the Process

It’s always a bad idea to exaggerate the amount of a mechanic’s lien. While the exaggerating lienor may succeed in getting the attention of

Despite Optimism for Select Sectors, CEO Confidence Index Hits Near Lows

HYDE PARK, NY—A survey released on March 5 by the Siena College Research Institute of more than 500 upstate business leaders showed optimism that several

Biden FY25 Budget Seeks Heavy Spending For DOT, Army Corps

WASHINGTON—Thanks to the funding levels that are part of the $1.2 trillion IIJA, President Joe Biden’s budget proposal for fiscal year 2025 is sticking with

PSC Approves $57.8M Rockland Power Line

ALBANY —The New York State Public Service Commission recently approved plans by Orange and Rockland Utilities, Inc., for a new two-year electric system construction project,

Safety Watch – Fall Protection Must Be Provided to All Employees Working at Heights Greater than Six Feet

The Occupational Safety and Health Review Commission’s decision in Secretary of Labor v. Gate Precast Company reaffirms the safety requirements for construction companies that have

HVCIP Mid-Winter Meeting

HVCIP MID-WINTER MEETING

Ritz-Carlton, Naples, Florida • February 25 – February 29, 2024. 175 Members and Guests Convene to Discuss Management & Labor Concerns, Contracting

Yonkers IDA Helps Advance Teutonia Hall Project With $17.5M Incentives for Riverfront Development

YONKERS, NY—The long-anticipated redevelopment of the Teutonia Hall site on Buena Vista Avenue here is primed to move forward following final approval of financial incentives

Orange County Advanced Manufacturing Project Secures New York State Shovel-Ready Grant

MONTGOMERY, NY—A proposed project to locate a multi-building advanced manufacturing complex at the Aden Brook Commerce Park here was one of seven winners of the

Financial Management – Keep Good Records on PPP Loan Forgiveness. Lookback on SBA Challenge is Up to 10 Years

Many companies that have submitted documentation to the Small Business Association and that have had Paycheck Protection Program loans forgiven may think they are home

Making a Career of it

Making a Career of It Joseph Szabo Journeyman – Carpenters Local Union 279 Age: 36 Recent Employers: WD Installations, Inc. Recent Projects: Lasdon Park main

What’s New & Who’s News

A roundup of what’s new and who’s in the news both locally and in the state.

Building Trades Confident Road, Energy, Sewer Work Will Lead to Busy 2024

TARRYTOWN—Union building-trades officials in the Lower Hudson Valley express confidence that despite the economic headwinds and challenges of last year, several of the main economic

NYSDOT Lists 42 Projects, Valued at $376M, For Mid-Hudson Anticipated Lettings in 2024

POUGHKEEPSIE, NY—The New York State Department of Transportation recently released its anticipated project list for the 2024 letting season for the seven counties in the

TRIP Report Calculates Poor Roads, Bridges Cost New York City Area Motorists Nearly $37 Billion

NEW YORK—Roads and bridges that are deteriorated, congested or lack some desirable safety features cost New York motorists a total of $36.7 billion statewide annually—$

Coalition Demands More State Funding To Repair Hudson Valley’s Crumbling Roads

ELMSFORD, NY—A major coalition led by the Construction Industry Council of Westchester & Hudson Valley and construction trade unions is demanding that state lawmakers allocate

Attorney’s Column – Relying on Drawings Alone for Calculating Bid Failed to Show a Project’s True On-site Conditions

When first deciding to undertake a construction project, be it public or private work, contractors often start by reviewing the drawings—the graphic representation of what

Poughkeepsie Firm Named Apparent Low Bidder On Mid-Hudson Forensic Hospital Asbestos Job

ALBANY—The New York State Dormitory Authority has reported on its website that an apparent low bidder has been named for the first project in what

Safety Watch – Tragedy Illustrates Why Contractors Must Coordinate With Engineers to Establish and Update Rigging Plans

The decision in Secretary of Labor v. Tower King, II, Inc. should serve as a reminder to the construction industry, and companies specifically involved in

Annual CIC NYSDOT Region 8 Construction Safety Seminar

HYDE PARK, NY—The annual CIC/NYSDOT Region 8 Safety Seminar held at the Culinary Institute of America here on Tues., Jan. 30, drew a record attendance

Financial Management – Design-Build Procurement to Shape Future Of Construction for City of New York: DDC

In an effort to increase efficiency and reduce complexity in the construction process, the recently appointed Associate Commissioner of Alternative Delivery for New York City’s

Albany Update – NY State Awards $215M In Water Quality Funding

ALBANY—In separate announcements on Feb. 15, New York announced awards of more than $166 million in grants to 187 water quality projects throughout the state.

Washington Update – New EPA Air Quality Standard Termed an Overreach by ARTBA

WASHINGTON — The Biden-Harris Administration on Feb. 7 finalized a significantly stronger air quality standard that officials say will better protect America’s families, workers, and

Teamsters L.U. 456 Creates On-the-Job Trainee Program

ELMSFORD, NY—Teamsters Local 456 has created an on-the-job training program that enables a CDL-licensed driver/trainee to ride along in construction vehicles with an experienced driver/employee

Westchester IDA Marks Banner Year in 2023 With $2B, Propelled by Regeneron Expansion

WHITE PLAINS—The $1.8-billion expansion of Regeneron Pharmaceuticals has once again put economic development activity incentivized by the Westchester County Industrial Development Agency in the billions

Local Sales Taxes Grew 4.2% in NY State To $23 Billion in 2023, Comptroller Reports

ALBANY—Local government sales tax collections in New York State, fueled by growth in New York City sales taxes, totaled $23 billion in calendar year 2023,

Real Estate Broker’s Forecast Sounds Alarm on Office Sector

WHITE PLAINS—A panel of real estate brokers and developers offered a candid and unvarnished assessment of Westchester County’s multifamily, industrial, medical and office markets heading

Putnam County Exec. Calls for Restoration Of $60-Million Reduction to CHIPS Program

ALBANY—In testimony provided at the New York State Joint Legislative Public Hearing on the 2024 Executive Budget on Transportation earlier this month, Putnam County Executive

Filings for Large Multifamily Projects In NYC Remain at Historic Lows: REBNY

NEW YORK—The Real Estate Board of New York’s recently released New Building Construction Pipeline Report for the fourth quarter of 2023 states that New York

Viewpoint – Rockland’s Office of Buildings & Codes Issues Record Number of Violations, Fines Since 2022 – by Ed Day

Two years ago this month, we fulfilled an order by New York State Department of State (NYSDOS) to assume all functions and responsibilities of the

Economic Outlook – The Economic Effects of Cyber Attack

In our interconnected world, where the global economy relies heavily on digital infrastructure, the specter of cyber attacks looms large. Federal regulators often have said

White Plains Granted $10M in Downtown Revitalization Funding by New York State

WHITE PLAINS, NY—The City of White Plains was honored this month as a recipient of this year’s Downtown Revitalization Initiative Mid-Hudson Region and will receive

What’s New & Who’s News

A roundup of what’s new and who’s in the news both locally and in the state.

Gov. Hochul Seeks Large NYC Projects, Housing, Climate Change Goals in Her FY25 Proposed Budget

ALBANY—Gov. Kathy Hochul used her two spotlight appearances here this month to lay the groundwork for what her administration will seek in the annual budget

‘Blistering Pace’ of Growth in Bridge, Highway Construction, ARTBA Reports

WASHINGTON—Roadbuilders and their suppliers can expect a banner year in 2024, with industry experts projecting record spending on infrastructure projects thanks to the bipartisan Infrastructure

NYSDOT Updates Public on Progress On Rte. 17/I-86 Conversion/Exit 122 Job

TOWN OF WALLKILL, NY—The New York State Department of Transportation hosted public information sessions on Jan. 17 at the Town of Wallkill Community Center and

CIC Marks Milestone 45th Anniversary in 2024 With Special Presentations Planned at Events

TARRYTOWN, NY—The Construction Industry Council is celebrating its 45th anniversary this year with a host of events to mark the milestone since its first full

Attorney’s Column – Court Frowns on Claims Asserted Outside A Contractor’s Own Chain of Contract Privity

Anyone who has undertaken a construction project knows there are many activities to be coordinated, with many different people performing these activities. It is also

Warmer Winter Helping Construction DPW Projects Advance in Region

CHESTNUT RIDGE, NY—The head of the Rockland County Highway Department recently told CONSTRUCTION NEWS that these past two milder winters in the region has allowed

Next Generation Leader – Andrew Griffin

Next Gen Leaders Profiles of the Industry’s New Generation Andrew Griffin Age: 25 Current Employer: Corgan / NYC Position / Job Title: Project Specialist College

Teamsters L.U. 456 Hold Session on Drug Testing Protocols for CDL Employers, Owner/Operators

ELMSFORD, NY—Teamsters Local 456 held an information session on Jan. 11 at the union’s headquarters here, entitled “Drug Testing Protocols & Procedures,” for companies with

NYC Metro Housing Costs Soar by 68% in Last Decade

ALBANY—Housing costs in New York City and the surrounding suburbs have skyrocketed by more than 68% over the last decade, the largest increase among selected

Safety Watch – Install Traffic Control Devices, Legible Control Signs At Points of Hazard During Roadwork Activities

The decision in Secretary of Labor v. Brubacher Excavating Inc. & Traffic Control Services reminds us that construction companies conducting paving and excavation operations in

Financial Management – NYC Banking on Surge in Transit-Oriented Projects

With transit-oriented development projects on the rise, the Port Authority of New York and New Jersey is also continuing its redevelopment efforts at three major

Albany Update – State Opens Applications for $325M In Grants For Clean Water Infrastructure Projects

ALBANY—New York State is making $325 million in grants available for clean water infrastructure projects through the next round of the state’s Water Infrastructure Improvement

Regeneron Buys Avon Property in Suffern; Plans $138M Spend for New R&D Complex

SUFFERN, NY—In addition to the $1.8-billion expansion Regeneron Pharmaceuticals is now advancing in Westchester County, the company announced it will invest another $138 million in

What’s New & Who’s News

A roundup of what’s new and who’s in the news both locally and in the state.

$450M Mid-Hudson Psychiatric Center To be Built with PLA for Local Trades

NEW HAMPTON, NY—The New York State Dormitory Authority said on Dec. 14 that it has released the first bid in connection with the “New Forensic

Federal Infrastructure Law’s Impacts Felt Increasingly Across America

WASHINGTON—States have committed federal funds to support more than 56,000 eligible transportation improvements in all 50 states during the last two years, spanning nearly every

New York State to Chip in $1 Billion For $10B Albany Nanotech Complex

ALBANY—New York State announced on Dec. 11 a $10-billion partnership with leaders from the semiconductor industry, including Armonk-based IBM, Micron, Applied Materials, Tokyo Electron, and

Millions of Construction Workers Are Illegally Misclassified, Costing Government, Taxpayers $22 Billion in Lost Revenues

A pernicious employment practice—called misclassification— is used by unscrupulous employers to avoid paying their share of payroll taxes and to evade certain responsibilities and liabilities

Con Edison Ends Westchester County Natural Gas Moratorium

ARMONK, NY—Natural gas hookups are coming back to Westchester County after a fourand- a-half-year pause. Con Edison is set to end the moratorium affecting most

Attorney’s Column – New Law Creates Confusion in Attempt to Clarify Substantial Completion and Maximum Retainage

In 2002, the New York State Legislature attempted to address the problem of perpetually late payments to contractors and subcontractors in the private sector by

Next Generation Leader – Taylor Reilly

Next Gen Leaders Profiles of the Industry’s New Generation Taylor Reilly Age: 23 Louis G. Nappi Scholarship received: 2018, 2019 Title & Employer: Wholesale Florist,

Albany Update – More Than 1,000 Speeding Tickets Issued In Work Zones in Hudson Valley Region

ALBANY—As construction throughout much of New York State begins to wind down with winter weather setting in, New York State officials recently highlighted the year-end

Safety Watch – Adequate Lock-Out/Tag-Out Systems Must Be In Place to Prevent Employee Injuries: OSHASafety Watch –

The decision in Secretary of Labor v. Ward Vessel & Exchange Corporation reminds us that construction companies must have adequate lock-out/ tag-out systems in place

Congressman Mike Lawler Discusses ‘Hot Topics’

ELMSFORD, NY—Congressman Mike Lawler (R-17CD) met with more than 60 members of the union Building Trades on Nov. 28 at the Teamsters Local 456 Union

Financial Management – An Update on Research and Development Credits

The availability of the Internal Revenue Section (IRC) Section 41 Research and Development (“R&D”) tax credit for construction companies stems from the recognition by the

Finally, MGM Resorts Unveils Empire City Expansion Plan

YONKERS—MGM Resorts International unveiled its vision late last month to transition Empire City Casino by MGM Resorts into a world-class entertainment destination—with the title of

Creedmore Massive Housing Plan Redo In Queens Gets Major Boost from Albany

ALBANY—The Creedmoor Community Master Plan, a massive mixed-use project to redevelop underutilized land at the 125-acre Creedmoor Psychiatric Center campus in Eastern Queens, received a

NYPA Seeks New Corporate HQ In Downtown White Plains CBD

WHITE PLAINS—The New York Power Authority is currently reviewing proposals for a brand new 250,000-square-foot Class A state-of-the-art corporate headquarters in Downtown White Plains and

State to Fund $30M for Rye Lake Filtration Plant, One of 156 Local Water Infrastructure Projects

ALBANY—In what will be the first funding awarded through the $4.2-billion “Clean Water, Clean Air, and Green Jobs Environmental Bond Act of 2022,” New York

Economic Outlook – Unpacking the U.S. Dollar’s Complicated Role As the Reserve Currency to Stabilize Markets

Unpacking the U.S. Dollar’s Complicated Role As the Reserve Currency to Stabilize Markets

The value of a nation’s currency (in this case the U.S. dollar)

South Bronx Hailed for Economic Growth Despite COVID Pandemic Challenges: Report

ALBANY—The COVID-19 pandemic hit the South Bronx especially hard, but the area’s economy has shown resiliency, according to a report released recently by New York

What’s New & Who’s News

A roundup of what’s new and who’s in the news both locally and in the state.

Albany Update – Yonkers Contracting Completes Nearly $45M Pavement Improvement Project on Section of NYS Thruway

ALBANY—New York State officials recently reported the completion of a $44.6-million pavement improvement project on the New York State Thruway I-87 in a critical corridor

Report: New York State IDAs Generated $141 Billion In Wages; Created, Retained 1.3-Million Jobs in 2021

ALBANY—In light of some criticism being leveled against Industrial Development Agencies in New York State, particularly the need and financial returns of incentives granted to

Rockland Christens New $40-Million Complex That Houses County’s Highway Department

CHESTNUT RIDGE, NY—A project in Rockland County that has been debated, advertised for bid, withdrawn, then moth-balled and delayed for nearly six decades, has finally

Guest Viewpoint – Misclassification of Workers Undermines Fair Construction Practices, Hurts All Trades

In the cutthroat competition of the construction industry, the relationship between employers and workers can be difficult to navigate. Something as simple as how you

13th Annual CAI Seminar for P.E.s Draws Dozens to Earn 6 PDH/HSW Credits

TARRYTOWN, NY—The always-popular professional development seminar, presented annually by the Construction Advancement Institute (CAI), drew a capacity audience last month for a program entitled “ENGINEERING:

Attorney’s Column – Court: ‘Adjoining’ Properties to be Protected During Excavation Need Not Be Abutting

It has long been the law that owners and contractors who perform construction activities on a property can be held liable for damages caused to

Obituary – O.L. ‘Peter’ Bibeau

BOCA RATON, FLA—Harold Vogt, the longtime leader of The County Chamber of Commerce (now operating as The Business Council of Westchester), died on Sept. 28

Obituary – Mortimer L. Downey, III

Mortimer L. Downey III, who for 65 years was a top official and advocate for mass transit, passed away on Nov. 2 at the age

100 Years Strong – H.O. Penn Celebrates Centennial Of Challenges and Achievements

POUGHKEEPSIE, NY—H.O. Penn staged a grand gathering at its headquarters here in early September to cap off the company’s ongoing centennial celebration in business. Scores

From the Archives – H.O. Penn Meets The Challenges of 9/11

NEW YORK—Four months after the attacks that devasted lower Manhattan, Chief Executive Officer Thomas Cleveland had a newfound appreciation for his company and the employees

Soaring Road Construction Costs Threaten State and Local Projects

TARRYTOWN, NY—Highway and street materials have increased 21% since last year due to hikes in petroleum-based energy costs and other material products in addition to

Safety Watch – Tree Trimming Work Requires Documented Training, Feasible Methods to Reduce and Eliminate Harm

The recent decision in Secretary of Labor v. Asplundh Tree Expert, LLC discussed feasible and effective methods to reduce or eliminate harm to employees performing

What’s New & Who’s News

A roundup of what’s new and who’s in the news both locally and in the state.

Financial Management – Both Opportunities and Challenges for Construction Loom in the Face of Infrastructure and Resiliency

The Inflation Reduction Act’s gift of funding and new capital projects on the horizon are promising and exciting for all in our industry. However, as

Albany Update – Business Council of NYS Sounds Alarm On Impacts of State’s Energy Policies

ALBANY—The Business Council of New York State announced recently the first of several state-wide information campaigns designed to educate New York voters on the impacts

NYC Region Enters New Era of Mega Projects As Feds Appropriate $10B+ for Tunnels, Bridges